Inside KibbeTech: Building High-Performance Pre-Runners and Trophy Trucks

Pre-Runner and Trophy Truck Builds: Behind the Scenes

The latest project at KibbeTech delves into the intricate process of building high-performance pre-runners and trophy trucks. With a focus on precision and attention to detail, the team provides a detailed look at their current projects, highlighting the complexity and craftsmanship involved. This article explores the ongoing work on Dan’s pre-runner and a trophy truck build, emphasizing the engineering and customization that go into these impressive vehicles.

Progress on Dan’s PreRunner

Chassis and Assembly

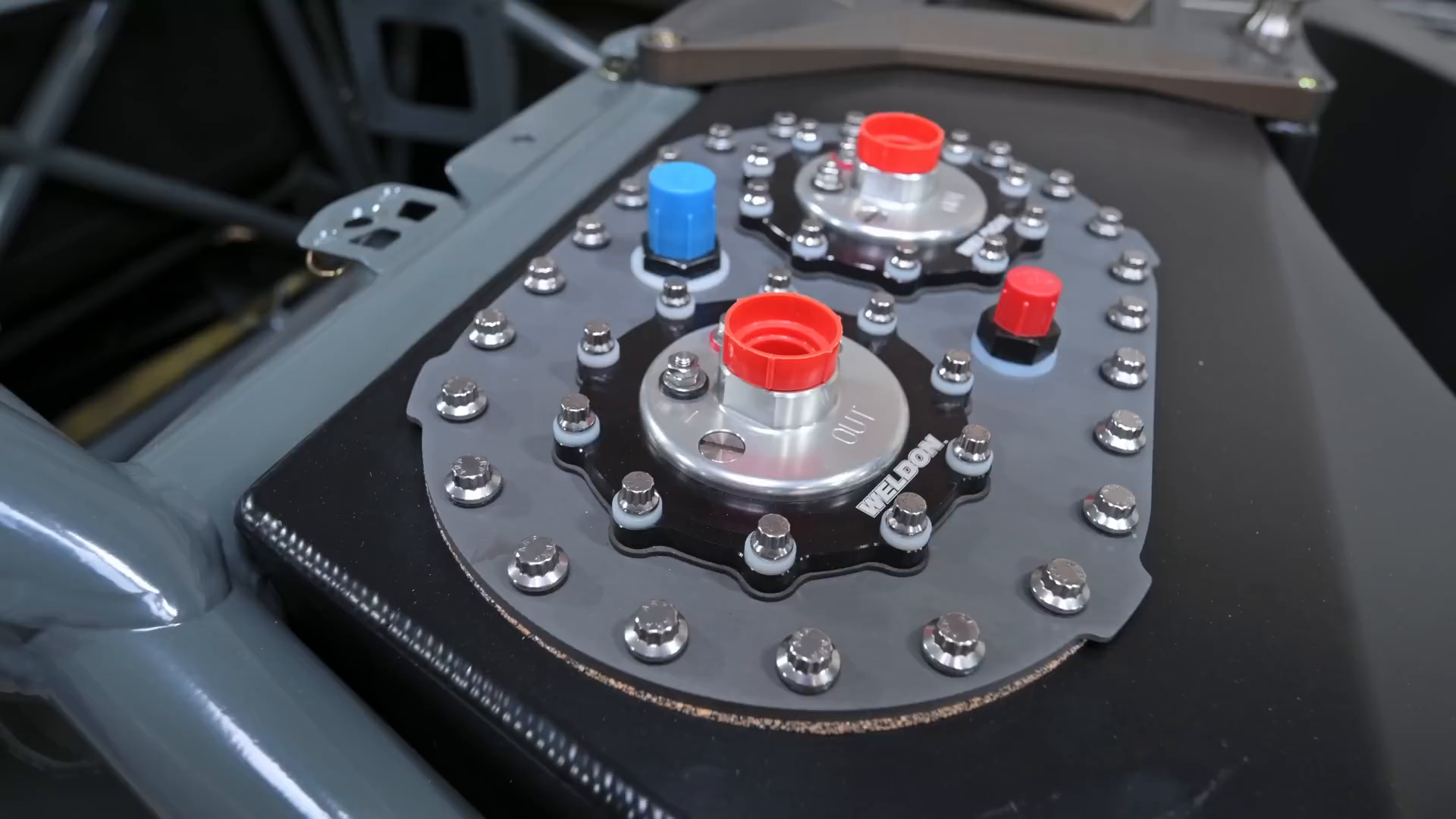

Dan’s pre-runner has returned from powder coating, painting, and Linex treatment. The initial assembly is underway, with the team focusing on fitting bulky components into the chassis. The fuel cell, now powder-coated black, securely sits within the frame, accompanied by anodized billet hold-downs. These elements not only enhance durability but also offer protection against fading. Additionally, the hardware has been upgraded to stainless ARP bolts, providing an aesthetic and functional upgrade.

Parts Preparation and Anodizing

The team at KibbeTech is meticulous in their approach, preparing a range of parts for installation. Rear trailing arms, upper links, and hubs are assembled and prepped, showcasing the use of high-quality components like stainless inserts for shock bolts. This attention extends to the anodizing process, where exposed aluminum parts undergo hard anodizing to ensure longevity and resistance to wear. Such strategic upgrades reflect the commitment to quality and performance.

Suspension and Engine Specifications

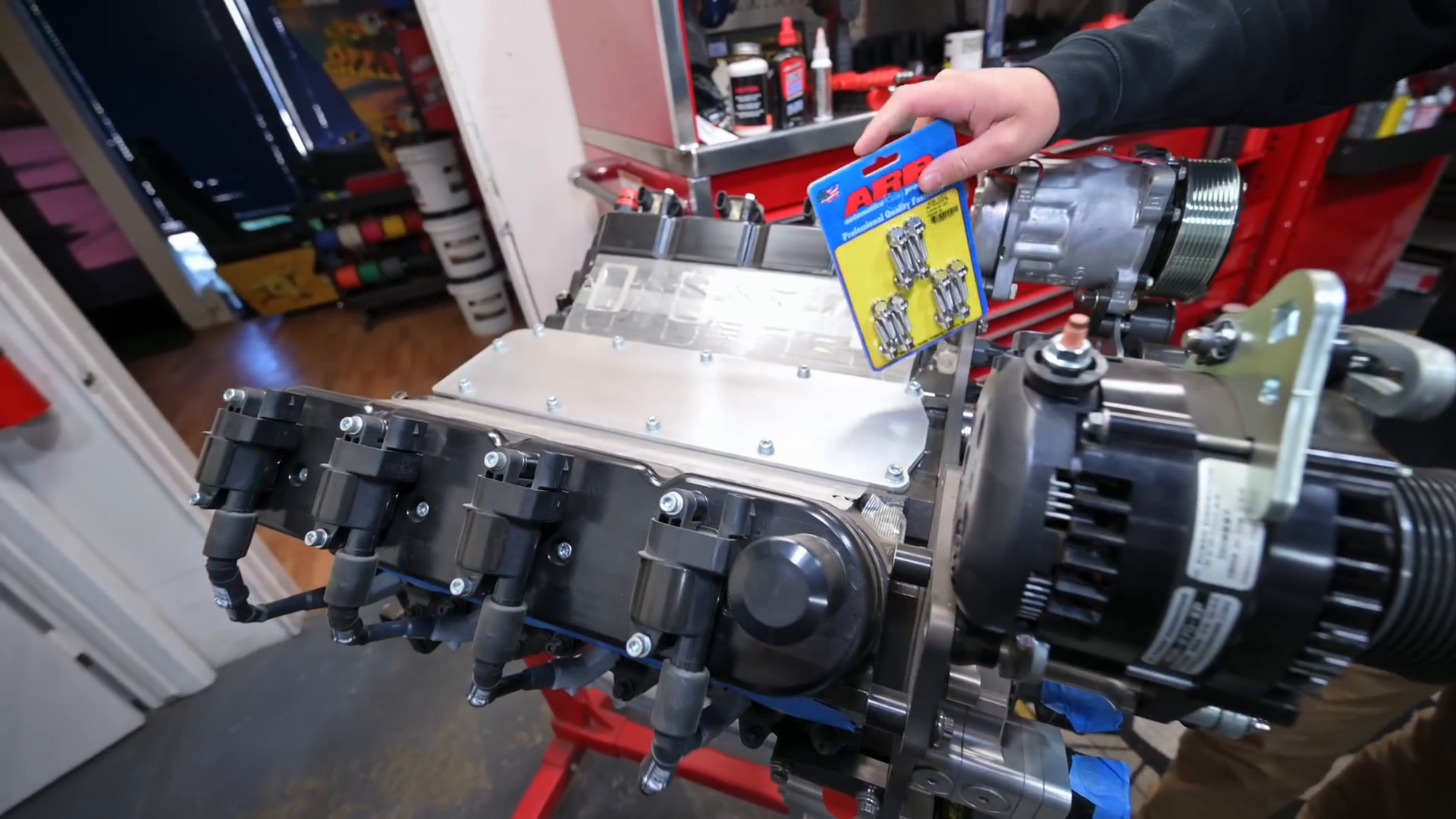

The suspension system for Dan’s pre-runner is carefully curated, featuring ProAm hubs and substantial bearings. The rear end utilizes a 36 Pline axle, polished for durability. The engine, a Redline LSX 454, is coupled with an ID Designs accessory drive, promising robust performance. Additional enhancements, such as a billet water pump and power steering solutions, further optimize the vehicle’s capabilities. These components together ensure the pre-runner is ready for high-speed desert adventures.

Check out KibbeTech on Instagram.

Trophy Truck Build: A Closer Look

Design and Layout

The trophy truck build embodies the pinnacle of off-road racing engineering. With a track width of 93 inches and a wheelbase of 125 inches, this truck is designed for speed and stability. It houses a powerful big block Chevy engine from Danzio, producing 975 horsepower. The Turbo 400 transmission and underdrive system ensure efficient power delivery, while the King shocks provide superior suspension performance across rugged terrains.

Shared Components and Customization

Interestingly, the trophy truck shares several components with Dan’s pre-runner, such as the bulkhead and trailing arms. This modular approach allows for interchangeable parts between pre-runners and race trucks, facilitating easier maintenance and upgrades. The truck is equipped with Triumph Performance’s M-Spec wiring, integrating advanced electronics, such as a Life Racing ECU and MOTEC PDMS for optimal control and performance monitoring.

Innovative Features

The trophy truck stands out with its advanced cooling system and fuel capacity. A custom-designed CBR cooling package ensures efficient heat management, critical for prolonged high-speed runs. The fuel cell, boasting a capacity of approximately 105 gallons, is equipped with dual dry brakes, enhancing safety and reliability. These features underscore KibbeTech’s commitment to building vehicles that excel in both performance and endurance.

Engineering and Technological Advancements

Billet Components and Anodizing

The use of billet components throughout these builds highlights a trend towards precision engineering and customization. Billet aluminum parts are stronger and offer more design flexibility compared to cast or forged counterparts. Anodizing these components not only protects them from environmental factors but also allows for aesthetic customization, aligning with owner preferences.

Integration of Advanced Electronics

The integration of advanced electronics systems, such as ECUs and PDMS, reflects the growing importance of technology in off-road racing. These systems provide real-time data and control, enabling precise tuning and performance optimization. As racing conditions become more competitive, such technological advancements become crucial in gaining an edge over competitors.

In summary, KibbeTech’s commitment to excellence is evident in their latest projects. The combination of cutting-edge technology, high-quality materials, and meticulous craftsmanship defines their approach to building pre-runners and trophy trucks. As these vehicles continue to evolve, they not only embody the thrill of racing but also showcase the innovative spirit of modern engineering. Stay tuned for future updates as these impressive machines come to life, ready to conquer the toughest terrains and push the boundaries of performance.

Categorized in: Trucks