Brenthel Industries’ New Facility: Expanded Trophy Truck Innovation

In 2022, Brenthel Industries embarked on a transformative journey by relocating to a significantly larger facility that spans 55,000 square feet. This move marks a major upgrade from their previous 13,000 square feet space, signifying not only expansion but also the evolution of their operations. The new factory accommodates multiple facets of their business, including Baja Kits, Friendthel Industries, and Ravelk, their CNC shop. This article explores the detailed layout and operations of the new facility, providing insight into how Brenthel Industries is managing their growth and enhancing their production capabilities.

A Comprehensive Facility Tour

The Showroom: A Work in Progress

The showroom at Brenthel Industries is still under development, with plans to display the latest race trucks, sand cars, and other vehicles. Currently, the space is filled with fiberglass race truck bodies, a temporary arrangement that reflects the dynamic nature of the business. The showroom is expected to become a focal point for showcasing Brenthel’s innovative designs and craftsmanship.

The Office Spaces: Centralized Operations

The office area houses various departments, including sales, marketing, and production management. The family-owned business has grown significantly, now employing 44 people. The office spaces are designed to facilitate effective communication and coordination among team members, playing a crucial role in supporting the company’s operations.

The Engineering and Design Hub

Brenthel Industries’ engineering and design department is where innovation takes shape. The team engages in CNC programming, 3D printing, and prototyping, ensuring that each component is designed with precision. The ability to test 3D-printed parts before proceeding to production allows for thorough evaluation and refinement of designs, ultimately leading to higher-quality products.

The Heart of Operations: The Trophy Truck Factory

The factory is the centerpiece of Brenthel Industries, where they produce 18 new trophy trucks annually and maintain an additional 15 for clients. This requires meticulous planning and execution, as the company participates in 35 races each year across various series, including Best in the Desert, SCORE, and NORRA. The factory is a hive of activity, with trucks at different stages of preparation, from initial builds to final race-readiness checks.

All-Wheel Drive Innovation

Brenthel Industries is at the forefront of developing all-wheel-drive trophy trucks, a relatively new concept in the industry. This innovation enhances performance and handling, marking a significant shift from the traditional two-wheel-drive models. The company is committed to rigorous testing and development to ensure these vehicles are race-ready before they reach clients.

The Importance of Standardized Preparation

Brenthel Industries prides itself on its standardized preparation process, which ensures consistency and reliability for each truck. The prep department adheres to a set pricing structure, providing transparency and predictability for clients. This approach is unique in the industry, setting Brenthel apart as a leader in quality and customer service.

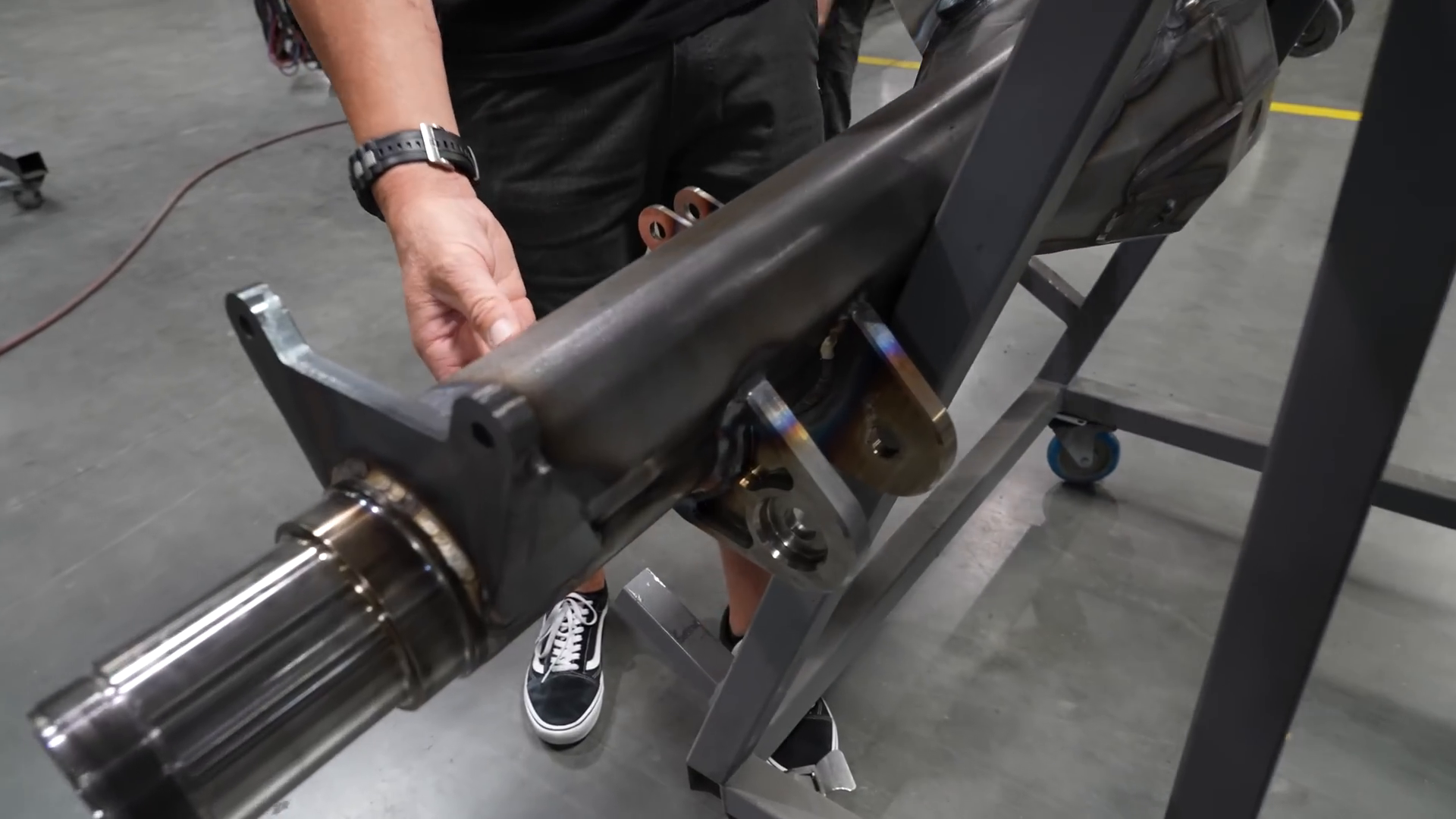

The Fabrication and Assembly Process

The facility’s fabrication department is equipped with state-of-the-art tools and equipment, including CNC machines, laser cutters, and press brakes. These resources enable the company to maintain tight control over the production process, ensuring that each component meets exacting standards. From welding to assembly, every step is carefully orchestrated to maximize efficiency and quality.

Luxury Pre-Runners: Combining Comfort and Performance

Brenthel Industries also produces luxury pre-runners, which offer the performance of a trophy truck with the added comfort of a fully enclosed cab. These vehicles are equipped with air conditioning and heating, making them suitable for both racing and recreational use. The luxury pre-runners are customizable, with options for extended cabs and various interior features, allowing clients to tailor their vehicles to their preferences.

Material Management and Logistics

Efficient material management is crucial for Brenthel Industries to meet production demands. The facility includes dedicated areas for material storage, staging, and distribution, ensuring that all components are readily available for assembly. This organization minimizes downtime and supports the company’s goal of producing high-quality vehicles in a timely manner.

Innovation in Inventory Management

The company employs advanced inventory management techniques, such as pre-assembled plumbing lines and standardized parts, to streamline operations. By maintaining a comprehensive stock of components, Brenthel can quickly address any issues that arise, whether it’s during a race or a routine maintenance check.

Conclusion

The expansion of Brenthel Industries into a larger facility represents a significant milestone in the company’s history. By enhancing their production capabilities and refining their processes, they are well-positioned to meet the growing demand for their high-performance vehicles. As they continue to innovate and evolve, Brenthel Industries remains committed to delivering exceptional products and services to their clients worldwide. The new facility not only supports current operations but also provides room for future growth, ensuring that Brenthel Industries can continue to lead the industry in off-road vehicle manufacturing.

Categorized in: Fabrication, Trophy Trucks, Trucks